Procedural Modular Resin Lattices

Overview: This small experiment details the process of creating the foundation for procedurally generated resin lattices. The objective is to generate sparse lattice structures that can be easily printed using a stereolithography (SLA) printer. Using an interchangable set of modular components, the implemented design would allow for lattices to be generated from a sparse voxel grid or binary scalar field. It is assumed that the description of the geometry represents a single connected component and that it is suitable to be printed with an SLA printer that requires generated support structures.

Procedural lattice structures

The design idea was to generate the fine modular components that could be used to procedurally generate any form of cuboid lattice that could be generated by a sparse voxel grid ![]() or binary scalar field

or binary scalar field ![]() where each grid intersection

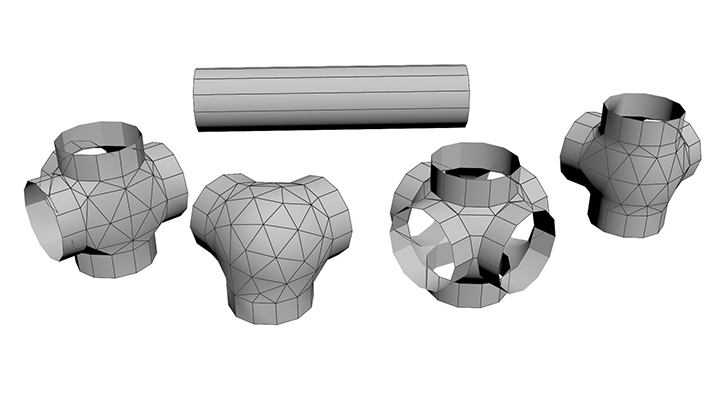

where each grid intersection ![]() . The set of modular components are defined as: T, elbow, 8-connector, corner, and straight. The objective of the modular lattice design is to:

. The set of modular components are defined as: T, elbow, 8-connector, corner, and straight. The objective of the modular lattice design is to:

- Create a set of modular components for procedural lattice structures

- Automatically convert voxel and scalar field data to lattices

- 3D print resulting lattice structure with high print quality

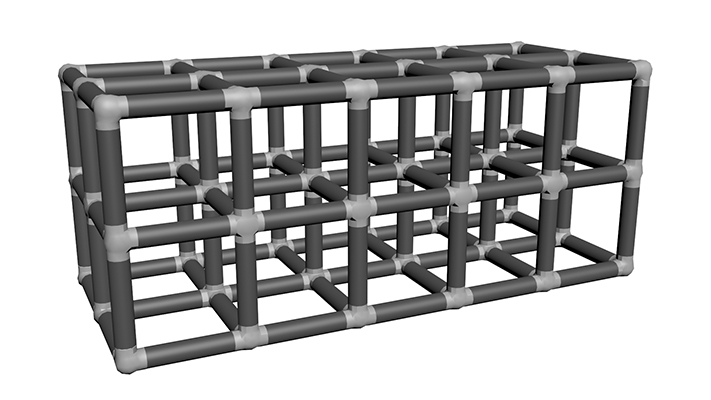

These provide a limited set of interchangeable components that can be defined by the immediate six direct neighbors of each grid element. This provides a simple 1-to-1 mapping between binary grid values and lattice generation. For basic shapes such as rectangular volumes, the shapes can easily be configured to create beam elements as shown below.

The procedural generation of the geometry from voxel or scalar fields provides an automated method for creating large shapes while minimizing print volume. Although the formulation is simple and easy to implement, there are some drawbacks to printing these types of lattice structures using SLA printers. The next section describes some of the challenges associated with printing this design on a consummer-level SLA printer.

SLA Lattice Printing

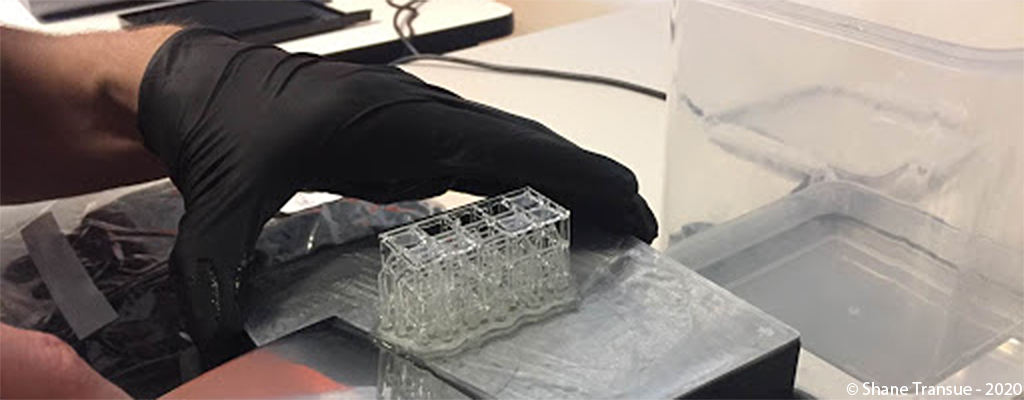

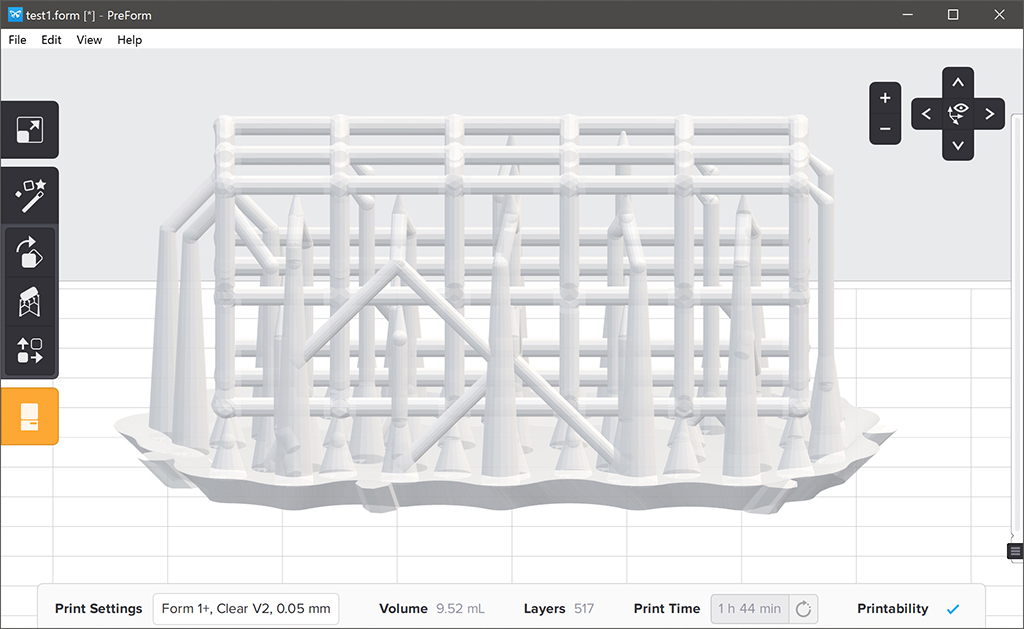

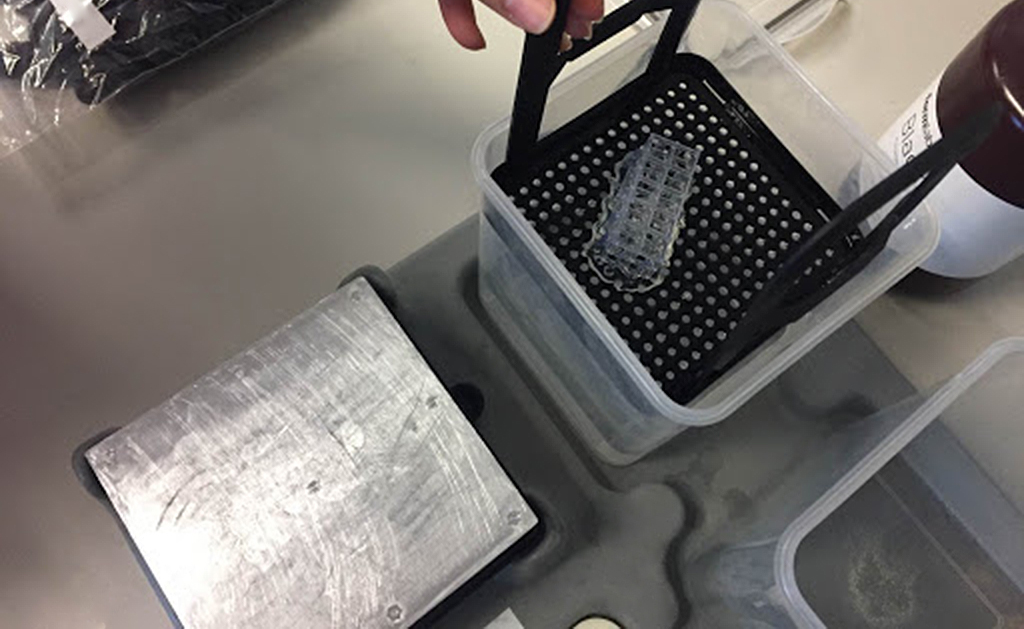

For smaller objects like the (5 x 2 x 2) beam, supports do not present a significant challenge. However, one of the significant drawbacks of generating sparse lattice structures is that the support structures required for the print will become increasingly tangled. This sort of restricts the generation of most objects to thin, shell, or concave objects due to the requirement for internal supports. Even if all of the supports can be generated correctly (using tree structures) the second problem is effectively removing them. If there are rigid connections within the interior of the object, they will become increasingly difficult to remove. With resin prints, this is specifically true due to the amount of force required to break the support from the lattice structure. Slicer contact points can be minimized, but this can also introduce the risk of mid-print breaks (with some resins this can be a significant problem). The 3D print of the lattice structure was configured in Preform, the slicer from the Form Labs 1+ SLA printer. Default settings were used (tree supports, normal print base, etc.). The resulting print was then cleaned using normal SLA post-print procedures (IPA + water rinse + UV Curing). The print was created using the FormLabs clear resin. The preform model and print outcome is shown below.

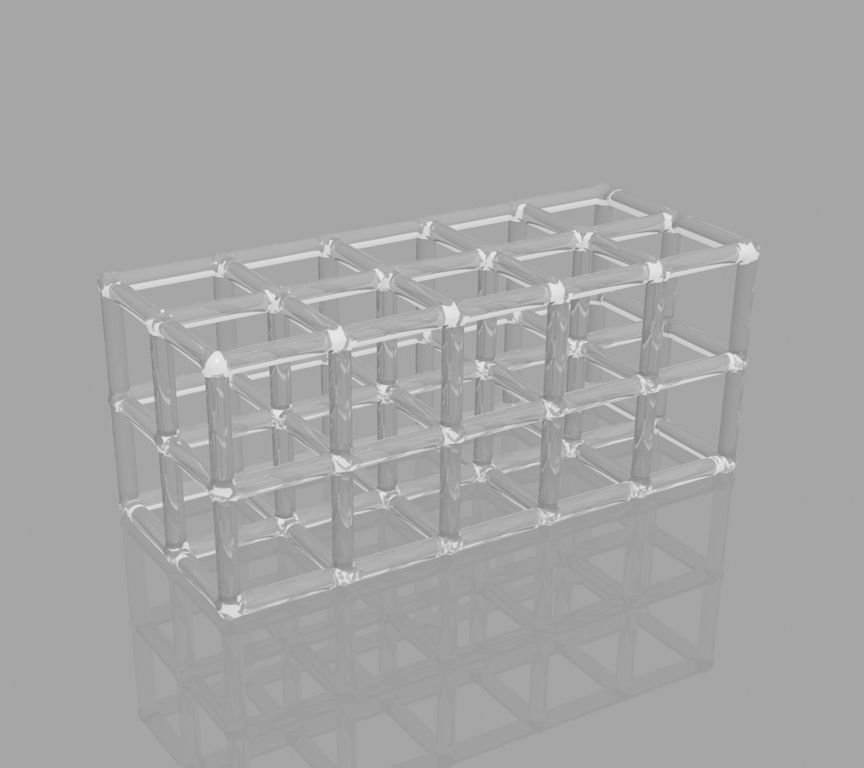

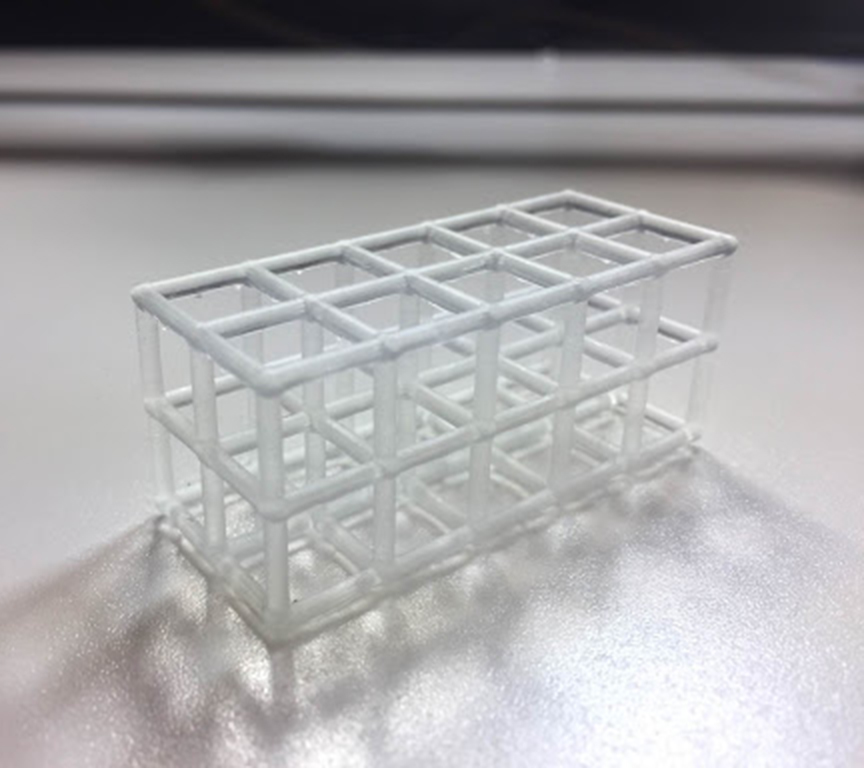

The generated lattice structure generates a hollow iso-surface that precisely represents the volume of the print area. This is useful for easily determining the total print volume but also provides a valid manifold mesh that can be rendered correctly. The image below on the left shows the theoretical print mesh rendered using ray-tracing. The image on the right illustrates the final print with the support and base materials removed. The outcome is essentially identical to the design. Depending on the post-print process, the resulting level transparency may not be as clear, but due to the thin nature of the elements, the resulting print is relatively clear.

The design and print of the sparse lattice structure is relatively straight forward. The largest problem is related to the removal of support materials. Obviously there are other solutions to this, including more expensive printers that do not require supports or those that provide dissoluble support materials. However, for consumer-level SLA printers, this will typically pose a problem for printing sparse lattice structures.

Conclusion and discussion

The design and implementation of the modular design was partly aimed at providing procedurally generated lattice structures; however, printing these shapes using hard resins with an SLA printer was only part of the objective. Since there are difficulties in printing these geometric structures with printers that require supports, there can be numerous improvements to either (1) reduce the number of support structures required for the print or (2) generate the geometry in a way that provides partial support through the print itself. But this design also has very specific benefits.

The designs provided by linking thin modular components is much more beneficial when printing the structure using different materials. Specifically, when the lattice structure is printed using flexible SLA resins. The thin connecting components then provide an ideal shape for deformation analysis due to the large deformations that can be imposed on thin cross-members. Based on this initial work, the objective was to generate geometry that would be well suited for large deformations based on simple geometry. The extension of this experiment is continued in the Thermal Deformation Analysis of Flexible Resins.